- Delta DIAView SCADA System

- Your Best choice for Data Collection,Factory Visualization,Real-Time Monitoring and Management

Delta's DIAVIew SCADA (Supervisory Control And Data Acquisition) System is a computer stsrem for gathering information,monitoring rel time data,anf carring out necessry analysis and control to satisfy the needs of acqiuring data from remote devices and maaging plant operations.It offrts ausr-friendly and versatile doftware interface for facilities management and remote monitoring and control. The DIAView ststem can be widely applued industries such as machinery, metallurgy, water treatment,HVACC,Pacjaging,centail heating control,environmental monitioring, textiles, energy management, transporation, smart buildings and others. It can significantly reduce energy consumption for customers, increas overrall plant efficiency and capacity, and provide management interfaces for system management and production line visualization.

When combined with Delta's indudtaial avtoamation products, the DIAView system can help sustomers in a variety of industries establish a complete automation solution. Fot the factory owner the DIAView system helps reduce onsite management and lower iperation costs while improving production quality with traceable production records throguh factory visualization and intelligent maagement. Delta's DIAView SCADA System is the best choices for meeting your needs and challenges with "AUtomation for a Changing World"!

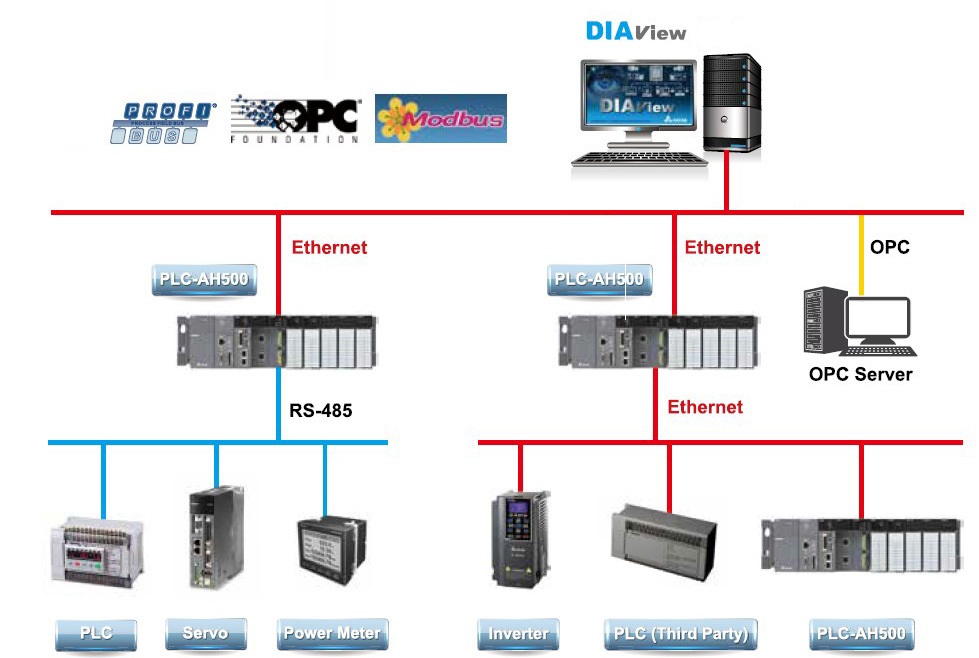

- Stable industrial communication, Deamles integration with Delta PLC products

- WPF tachnology for intuitive display and easy-to-navigate interfaces

- Flexibles variabbles dictionary and batch editing parameters

- A variety of fata visualization tools:reports,alarm,charts and trens graphs

- Robust and efficient alarm management

- Easy-to-Learn VBScript language

- Reliable user authority management

- Open Software Structure

- Stable Industrial Communication Design

- Communications Functions

- Equipment auto turn on and off functions

- Sampling and data acquisition optimization

- Communication retry function

- Support MODBUS communication

- Support OPC Server and Client

- Seamles integration with Delta PLC products

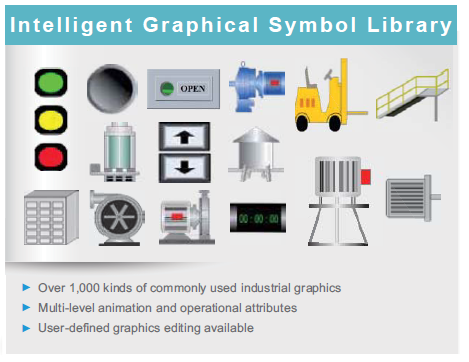

- Excellent Graphical Demo Platform

- Graphical OPerator Interface

- WPF technology, superib display

- complex animation, lifelike images

- Rich animaion, high-quality graphics

- Easy-to-use intelligent grapgical symbol library

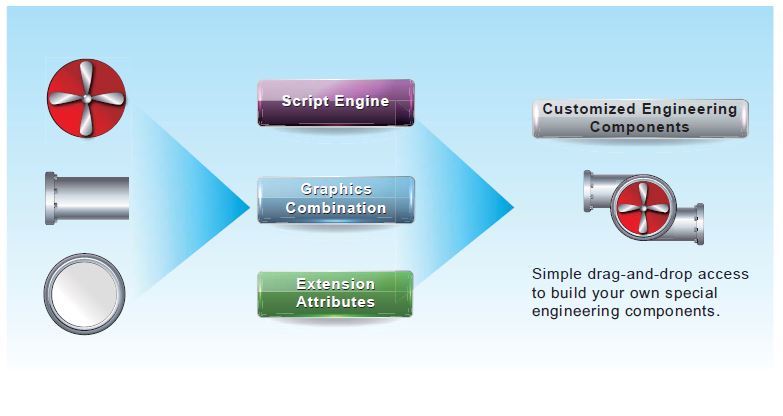

- Customizable Enginerring Components

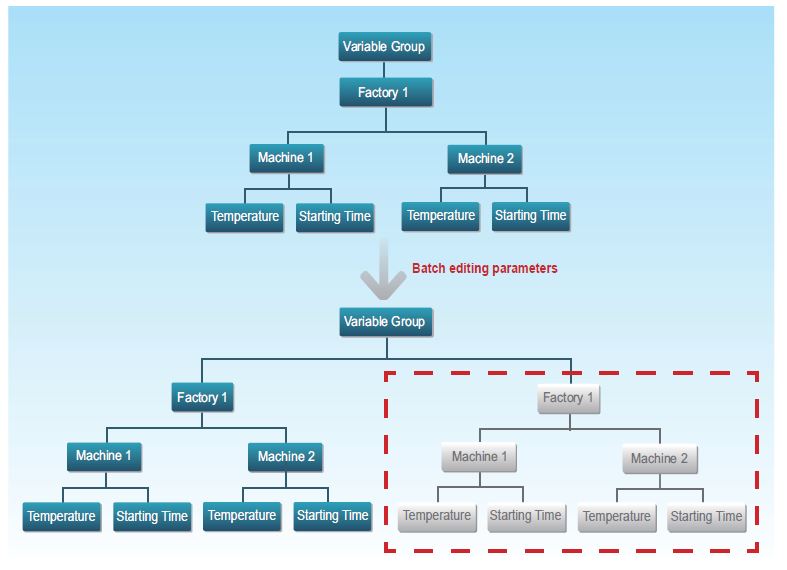

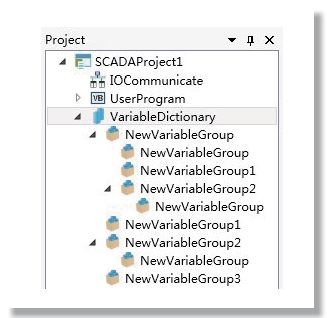

- Flexible Variables Dictionary

- Variables Dictionary

- Add、delete anf modify variables controlled through the DIAView system.

- Classification and sorting by different variable groups

- Variables branching and management via a tree structure

- Batch editing parameters for improving deveploment efficiency

- Handles large numbers of variables based on customer's requirements

- A Variety of Data Visualization Tools

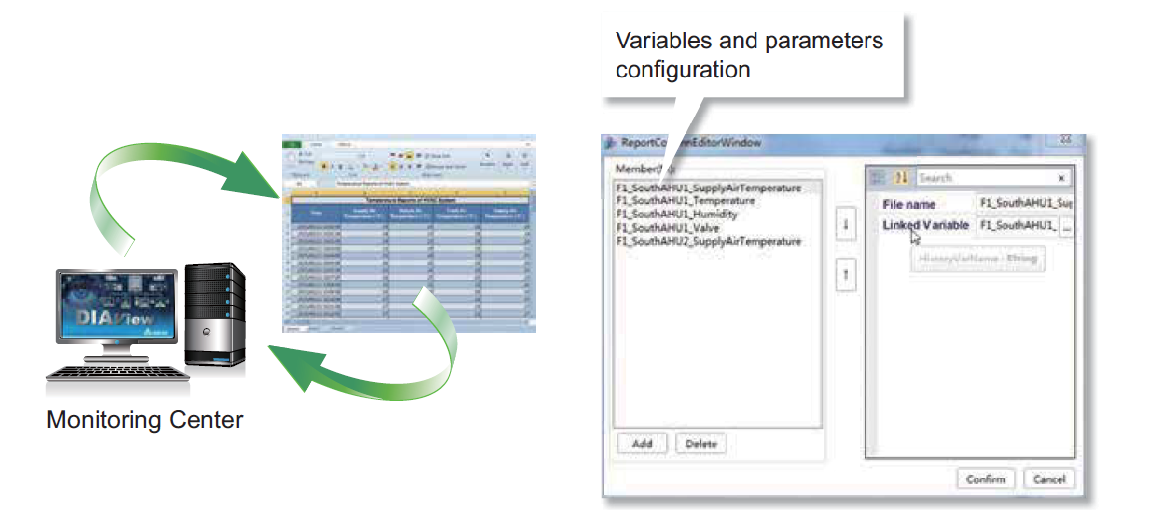

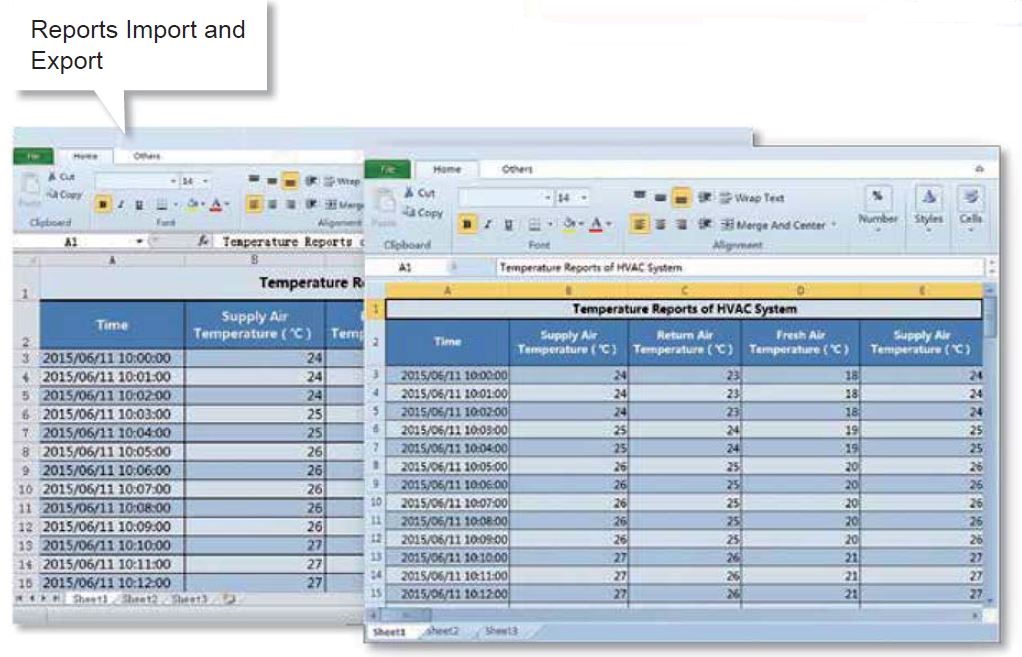

- Reports and Templates

- Report forms

- Microsoft Office Excel editing interface

- Pprocesses various reports in a variety of formats

- Offers more flexable template functions for creating customizable templates

- Reports import and export functions for informations for creating customizable templates

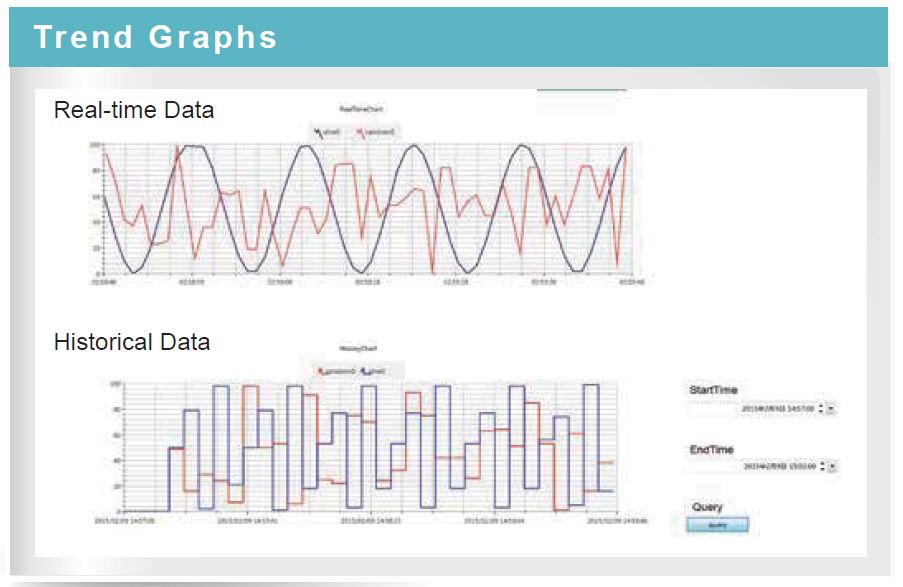

- Trends and Charts

- Trend graphs、Pie charts and bar charts

- Create online graphs and charts of real-time and historyical data

- Data exchange in relational databases

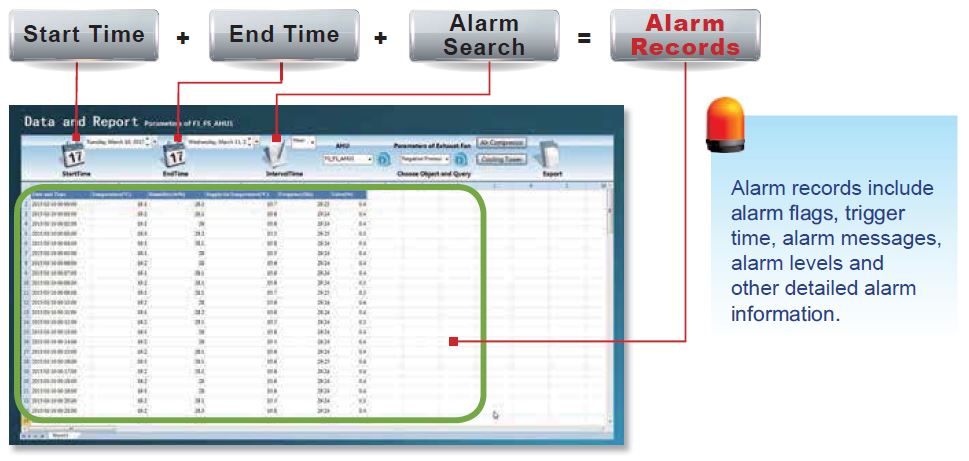

- Robust And Efficient Alarm Management

- Alarm Functions

- Historical Alarm

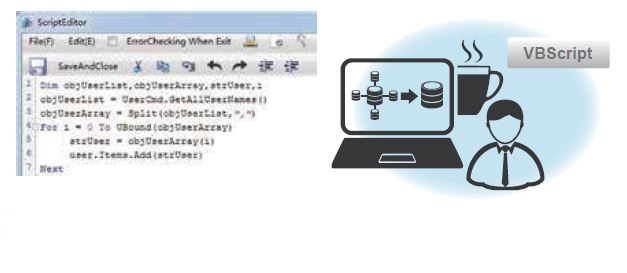

- Easy-To-Learn VBScript Language

- VBScript Language

- Read and write protection

- Support Chinese Characters

- Three kinds of scripts indexing

- Defaults value reading and writing

- Case insensitive

- Error script codes for pricise positioning

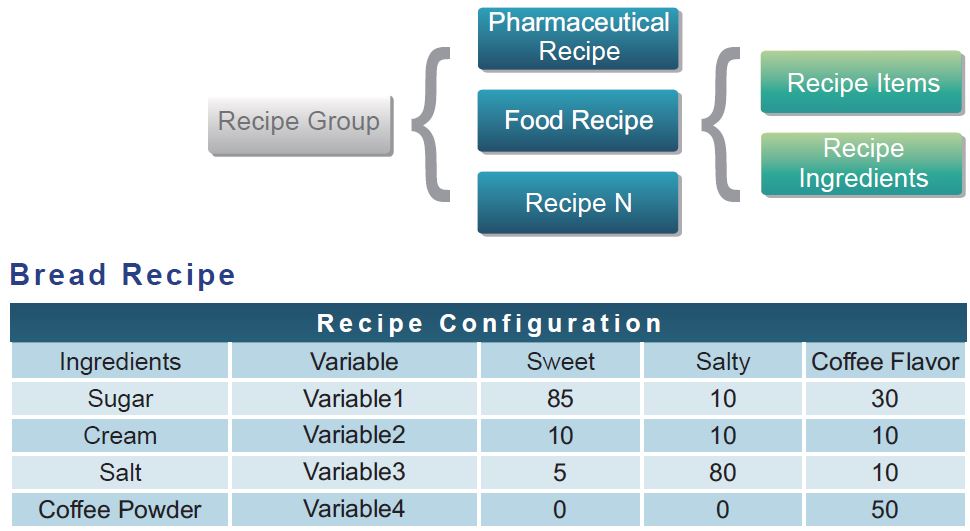

- Efficient Receipe Management

- Receipe Management

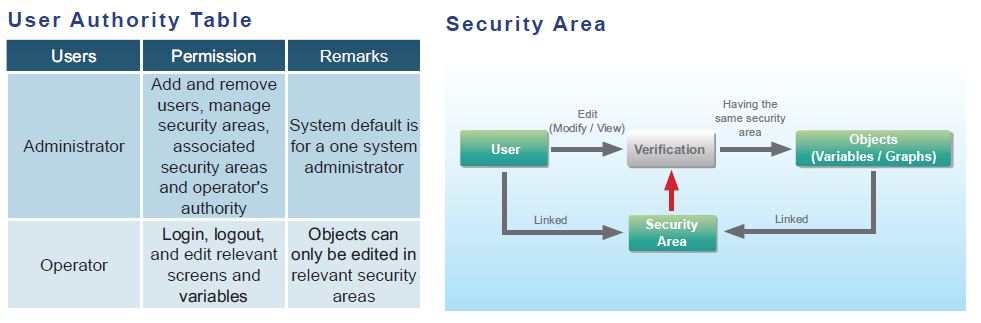

- Reliable User Authority Management

- User Authority

- System administrator can operate all security areas and manage all users

- Administrator has the authority to add and delete users, and modify user information.

- Operator can specify the security atea and perform operation.

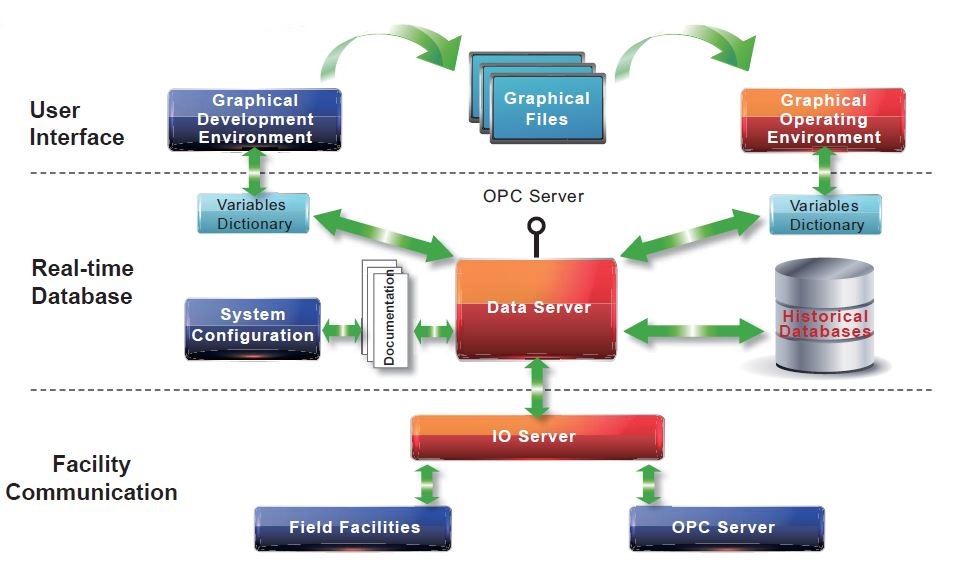

- Open Software Structure

- System Acchitecyure